26 January, 2026

Imagine a medical treatment that doesn’t just patch a wound but actually regrows your tissue from within. It may sound like a sci-fi technology you may have seen in some film or comic, but it is actually becoming a reality through a scientific revolution called 4D biomaterials. These are advanced materials designed to sense and react to their surroundings. While they are 3D-printed, they differ from traditional materials because they can adapt and change their shape to provide support during the healing process.

Conversely, for a long time the common approach in medicine was to use fixed supports to help the body recover. These materials were designed to be stable and unchanging, acting as a permanent structure to provide support where the body needed it. While these solutions have helped countless people, they remain the same even as our bodies heal, move, and grow around them.

Today, we are entering a new era of healthcare that is dynamic, smart, and capable of changing over time to work in harmony with our natural healing processes. This evolution is driven by materials that don’t just stay in place, but actually respond to the body’s needs, marking the transition from static medicine to living technology.

What are materials that change shape over time?

We were taught since childhood that we live in a 3D reality, where objects extend through space in three dimensions: length, width and height. This is how we perceive everything around us spatially.

But what happens if we add a fourth dimension? In the world of science and technology, that dimension is Time.

A 4D object is something that starts in a specific 3D shape but is built to change, move, or transform as time passes. It is no longer a static piece of matter, but a dynamic structure that evolves. If we think about it, we are already surrounded by many examples of this kind of behavior, as the biological world itself is inherently 4D. For instance, a seed, when exposed to specific environmental conditions, responds to those stimuli by evolving until it grows into a complete plant. Our bodies themselves are constantly adapting and changing, responding to both internal and external stimuli. This capacity for change lies at the very foundation of the evolution of living species, which relies on adaptation for survival.

This is why a technology truly compatible with the intrinsically transformative nature of biological matter must be able to evolve and adapt over time. It is the key step for the development of a new era in biomaterial technology, centered around a class of substances that represent the ultimate bridge between engineering and life: 4D biomaterials.

The (r)evolution of biomaterials

If a conventional biomaterial is a substance engineered to coexist safely with our biological systems, then a 4D biomaterial is its dynamic evolution. At its core, it is a material programmed to change its shape, properties or functions over time whenever it detects a specific environmental trigger, such as heat, light or chemical variations. This response is often made possible by using smart nanoparticles embedded within the structure that act as sensors to detect these changes.

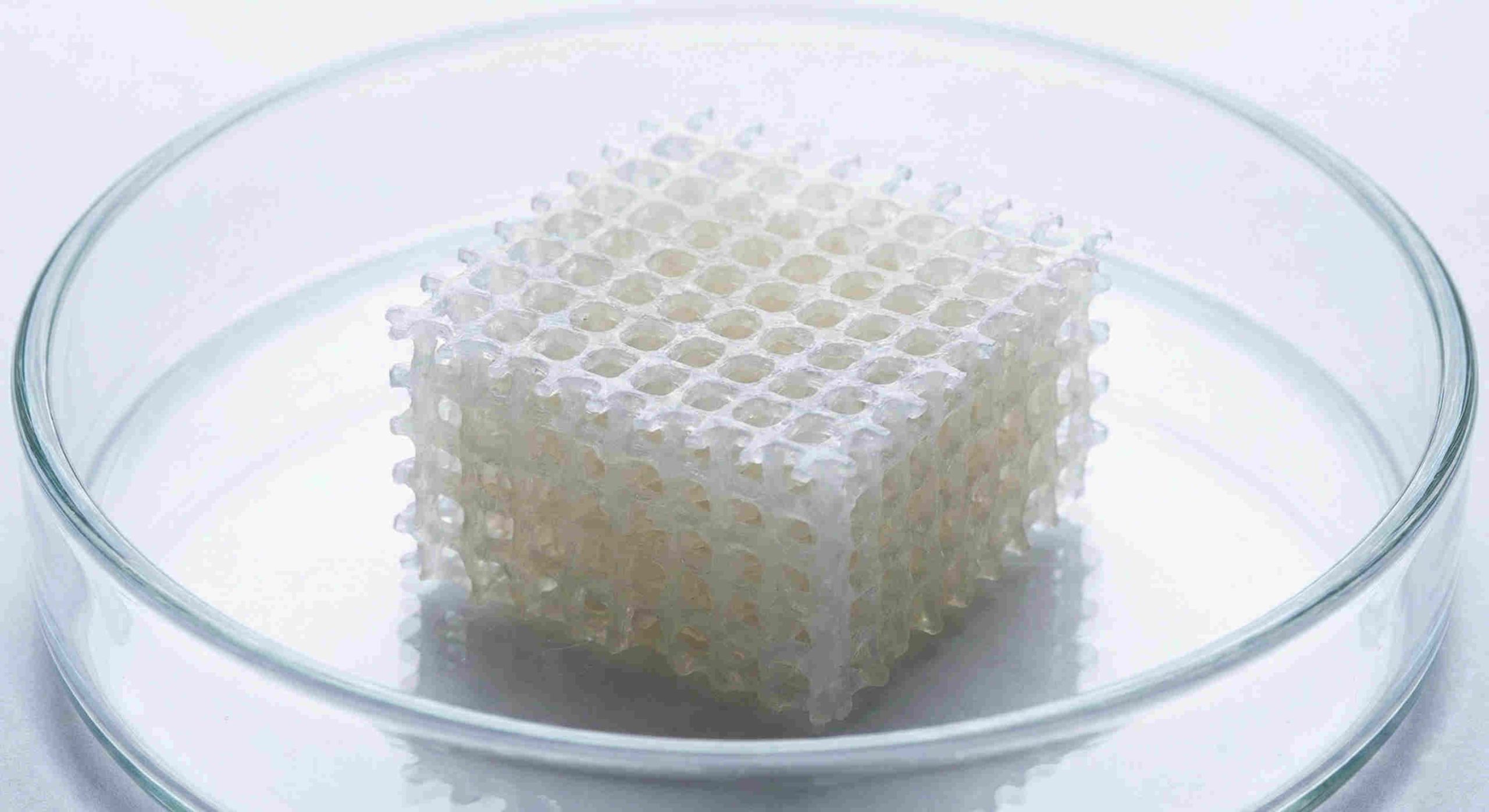

This shift represents a fundamental change in perspective. Instead of simply creating biomaterials that are inert and static, researchers in materials engineering and medical engineering are now looking to the very logic of living organic matter for inspiration. By studying how nature handles change, they have found ways to embed these same principles of adaptation and transformation directly into the material’s architecture.This transformation is brought to life through the power of bioprinting.

While traditional 3D printing is designed to create a finished, static object that remains exactly as it was printed, 4D bioprinting is designed to deposit extremely thin layers of bio-inks, which are specialized hydrogels that can be loaded with cells or bioactive molecules. This allows for the printing of dynamic, time-evolving materials, capable of integrating into a living organism.

The practical impact

The implications of this clinical leap are already redefining how we approach some of the most complex challenges in modern medicine.

In pediatric medicine, for example, the ability of a 4D structure to grow and evolve alongside a young patient solves a long-standing surgical dilemma: while traditional implants remain fixed, a child’s body does not. These new materials can be designed to expand and gradually resorb at the same rate as natural tissue, potentially ending the cycle of repeated, high-risk surgeries. This synchronized behavior extends to cardiovascular care, where vascular stents made from shape-memory polymers can now be delivered in a highly compressed state, unfolding autonomously only once they reach the target artery and sense the patient’s body heat.

Even the way we deliver medication is being transformed. Instead of systemic treatments that affect the whole body, 4D hydrogels can act as responsive carriers that activate to release their payload only when they detect specific chemical triggers, such as the unique pH levels of an inflamed tissue or a tumor. Whether it is a smart skin graft that morphs to follow the geometry of a healing wound or a scaffold that mimics the pulsing of an artery, these advancements show that technology is getting closer to the biological transformation mechanisms. This is particularly crucial in delicate environments like the human intestine, where the ability to precisely regenerate tissue layers could revolutionize how we treat chronic diseases from the inside out.

This is the scientific challenge being addressed by the DAEDALUS project, an ongoing initiative co-funded by the European Union. The project is currently working to apply these innovations specifically to the treatment of particular conditions of the intestinal mucosa, aiming to turn the potential of time-evolving materials into a concrete clinical reality.

Ready to see the future of healing? Explore our dedicated project page to discover how we are transforming intestinal care: https://www.daedalusproject.eu/.